Water pump station design manual

and maintenance practices of the relevant water agency. 2.4 Materials Design Additional paragraphs: The use of dissimilar metals within the pumping station pump well is to be avoided. If use of dissimilar metals is unavoidable, measures shall be taken to negate the effects of galvanic corrosion of equipment.

In this final blog discussing water types and pump station design, we will look at how sources of clean water can carry specific design implications. Clean water is in many respects the easiest water to pump. By definition, clean water is free from grit and solids and has no unusual water chemistry, eliminating a lot of the major concerns for engineering a pump station. However, there can be

However, a pump station becomes necessary when gravity outfalls are not economically or engineeringly feasible. The need for pump stations is a function of the highway geometric design rather than of climatic factors. Planners can design pump stations to be unobtrusive, efficient, and reliable.

Sewer Design Guide (Revised May, 2015) City of San Diego Public Utilities Department 9192 Topaz Way • San Diego, CA 92123 Tel (858) 292-6300 Fax (858) 292-6310

Pump Stations 1. Introduction ♦ Purpose of A Pump Station ♦ Security and Access Considerations ♦ Safety and Environmental Considerations 2. Pump Station Components ♦ Overview of Components 3. Pump Station Hydrology ♦ Methods for Design ♦ Procedure to Determine Mass Inflow 4. Pump Station Hydraulic Design Procedure ♦ Introduction

4.5.4 dry mounted submersible pump well design 5–4 4.6 pump control 6–1 4.6.1 water level regulation 6–1 4.6.2 electrical controls 6–2 4.7 valves and pumping station pipework 7–1 4.7.1 isolation of pumping stations from incoming flow 7–1 4.7.2 isolating pumping stations with submersible pumps 7–1

1-1. Purpose . This manual provides guidance where pressu re zones are required. Booster pumps and criteria for the design of high lift and water may be needed to handle peak flows in a booster pumping stations in potable water distri- distribution s ystem which can otherwise handle the bution systems. normal flow requirement s. Where a pump

Wastewater Pumping Station Design. At the March 16 meeting of the Brunswick County Board of Commissioners, the Wastewater Pumping Station Design Guidelines were approved for use by engineers and developers in designing Wastewater Pumping Stations. Please contact the Engineering Department at 910-253-2500 if you have questions regarding the

5.2.4 Pump Curves…..17 5.3 SUMMARY The purpose and intent of this Wastewater Lift Station Design Guidance Manual (hereafter referred to as “Design Guide”) is to provide City personnel and consultants for both Capital Improvement Program (CIP) and Private Development projects with a manual describing equipment standards and general design parameters for the design of wastewater lift

Pump station design manual 1. STORM SEWER PUMP STATION SIZING SPREADSHEET Francis Mitchell, M.S., P.E. F-MITCHELL@ATT.NET 2. Francis Mitchell, M.S., P.E. PAGE 1 STORM SEWER PUMP STATION SIZING SPREADSHEET Abstract: This spreadsheet is a tool to help the drainage engineer designs a storm sewer pump station by performing a level pool analysis of the pumping system, and storage areas. …

A Pump Stations shall be provided with pumps as outlined below. 1 Multiple pumps shall be used such that the pump station is capable of conveying the peak hourly wastewater flow to its desired outfall location with the largest single pump out of service. a In duplex pump stations, the pumps …

Flygt N-Technology Pumps N 3153 The Flygt N 3153 N-technology pump is self-cleaning and designed for sustained high efficiency… Pump Station Controllers SmartRun® Pump Station Controller The Flygt SmartRun™ pump station controller lets your pump take care of itself.

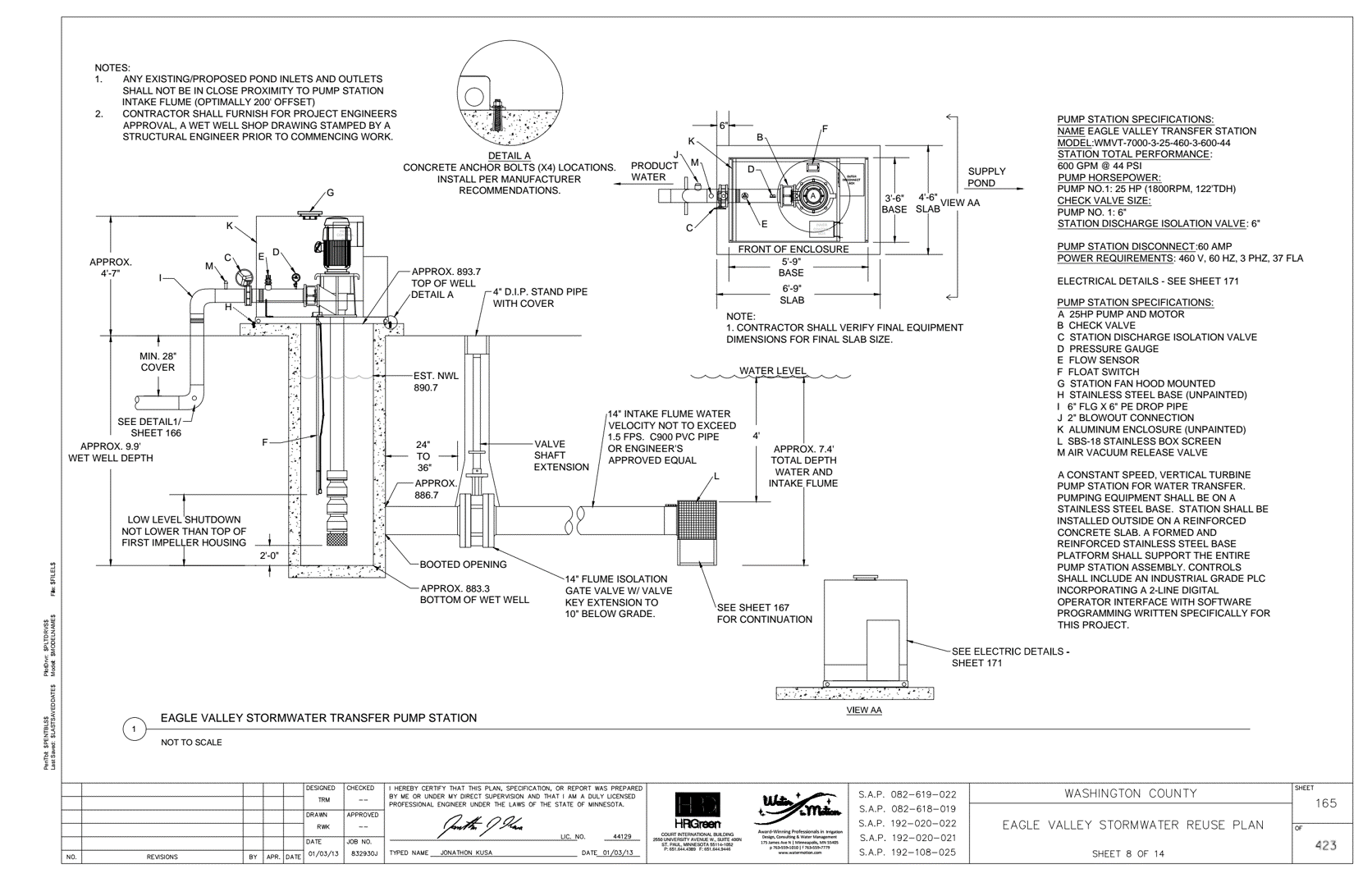

Highway Stormwater Pump Station Design. Highway Stormwater Pump Station Design, Hydraulic Engineering Circular No. 24 (HEC-24), provides a comprehensive and practical guide for the design of stormwater pump station systems associated with transportation facilities. Guidance is provided for the planning and design of pump stations, which collect

Water and Wastewater Standard Manual and Checklist (.pdf) The Water and Wastewater Standards manual contains standards for water, wastewater, reclaimed water mains and wastewater pumps stations specifications and approved materials for JEA service area’s infrastructure development and rehabilitation. This document also contains manhole standards.

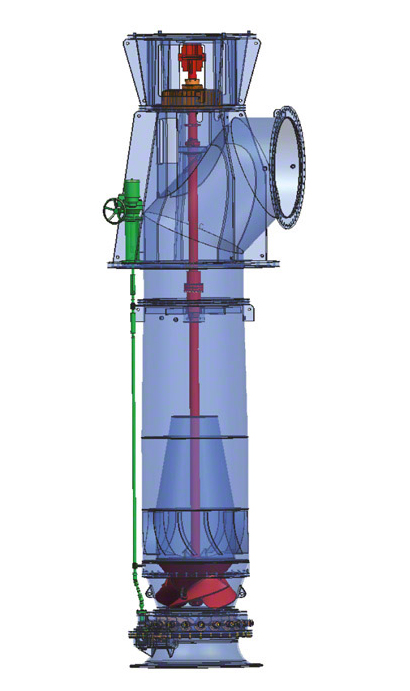

There are generally two types of pumps used for potable water pumping applications: the vertical turbine pump, line shaft and submersible types, and the centrifugal horizontal or vertical split case pump designed for water-works service. If the pump station and intake structure are to be located within a surface or underground

For a pump station with identical pumps, the required volume is smallest if the pumps start in sequence as the water level rises due to increasing inflow, and stop in sequence as the water level drops due to decreasing inflow. To minimize the required sump volume, the last pump to start should be the last pump to stop, i.e. cyclic alternation.

Pumping Stations Design For Infrastructure Master Program Engineering Faculty-IUG Dr. Fahid Rabah Water and environment Engineering . frabah@iugaza.edu. Lecture 5: Design of wastewater pumping stations. Dr. Fahid Rabah , PE frabah@iugaza.edu ٢ Lecture 5: Design of wastewater pumping stations. 5.1 General introduction Main components of WWPS:-Bar screen-Grit removal -Wet well or wet well + …

Pump Station Design Guidelines or want to be more hands on in the design process, we hope this manual is of help. OVERVIEW OF A TYPICAL JES SUBMERSIBLE LIFT STATION Figure 1 A typical submersible lift station by JES includes a wet well, dual submersible pumps, valves and an electronic pump control system. In smaller stations, the valves will often be installed in the wet well to save

as applicable. Reference documents include the Design of Wastewater and Storm water Pumping Station, Manual of Practice FD-4 as published by WEF, PVC Pipe Design manual published by Uni-Bell, Ductile Iron Pipe Design manual published by DIPRA, Hydraulic Institute Standards and the Recommended Standards For Wastewater Facilities, 1990 ed

SEWERAGE MANUAL Drainage Services Department 渠務署

Design Specifications & Requirements Manual 4 SEWAGE

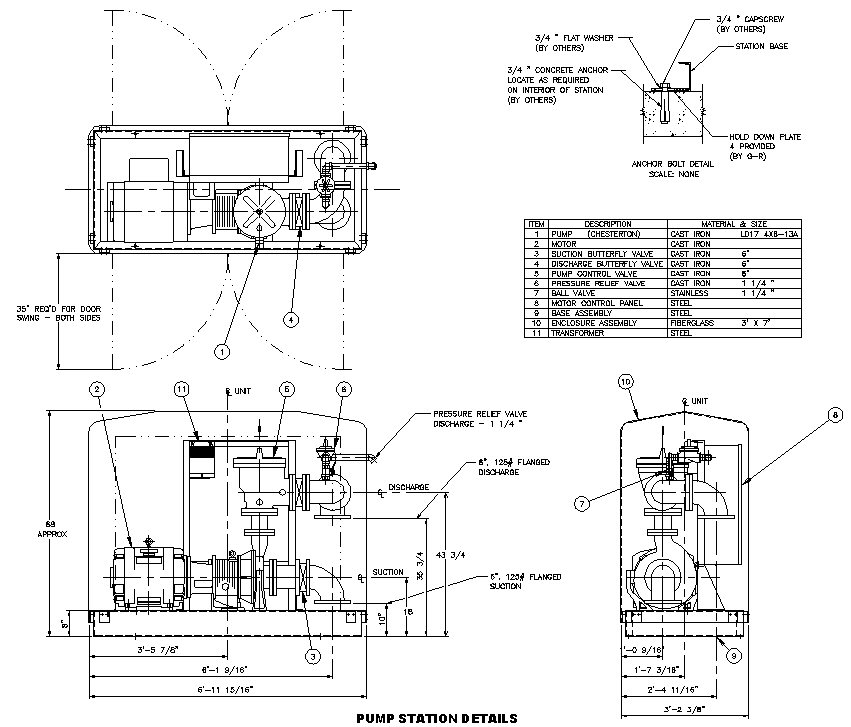

Wastewater pumping stations use a modular concept, while the pump pit, pumps and controls can be combined to suit specific requirements for each individual application. Material Pumping stations are made from high-density polyethylene (HDPE) or glass-fibre reinforced plastic (GRP).

Design recommendations for pump stations with miDrange centrifugal flygt wastewater pumps. 2 This document is intended for designers, planners and users of sewage and storm-water pumping systems that incorporate the range of 3152-3301 (20 l/s – 350 l/s) Flygt submersible pumps. The pump and sump are parts of an overall system that also includes a variety of structures and other elements such

Louisville and Jefferson County Metropolitan Sewer District (MSD) Design Manual, Table 5-2. WET WELL SIZING “Design of Wastewater and Stormwater Pumping Stations” Water Pollution Control Federation, Manual of Practice No. FD-4, 1981, p. 18, indicates that the wet well shall be sized so that the cycle time for each pump will not be less than

nearby natural drain. Drain pump sets shall be installed with 100% standby to pump out rain water and connected to the standby power. Rain-water harvesting shall not be provided in sewage pumping stations to avoid ground water pollution by raw sewage due to accidental spillage.

Traffic loads Structures Design Manual for Highways and Railways, HyD Wind load Code of Practice on Wind Effects in Hong Kong Reinforced concrete structures BS EN 1990 and BS EN 1992 (in general) – Pumping Station – BS EN 1992 (superstructure) and BS EN 1992-3 (substructure) – Tunnel lining – BS EN 1992-3 (liquid retaining

MDOT Drainage Manual Appendix 10-B Pump Station Hydraulic Design Example. 10-B-2 MDOT Drainage Manual 10.B.1 Introduction The following is a systematic procedure which integrates the hydraulic design variables involved in wet pit design. It incorporates the recommended design criteria and yields the required number and capacity of pumps as well as the wet well and storage dimensions

Pump Stations 10-8 MDOT Drainage Manual 10.3 GENERAL DESIGN CRITERIA The following pump station recommendations are being made with the objective of minimizing the cost of design, construction, operation, and maintenance of highway stormwater pump stations while remaining consistent with the practical limitations of all aspects.

Mechanical Design Standards are prepared to ensure that the Water Corporation’s staff, consultants and contractors are informed as to the Water Corporation’s design standards and recommended practices. Design standards are intended to promote uniformity so as to simplify design …

ENGINEERING DESIGN MANUAL Brunswick County Engineering Design Manual for Water & Sewer Systems (Rev 1.4 May 2019) STANDARD SPECIFICATIONS. Table of Contents (Rev 1.0 Sept 2012) 001.01 – Definitions and Terms (Rev 1.0 Sept 2012) 002.01 – UG Utility Lines and Structures (Rev 1.0 Sept 2012) 003.01 – Field Engineering (Rev 1.0 Sept 2012)

New Wastewater Pumping Station Development II. Pump Station Design Criteria The design criteria listed below are guidelines only, and site-specific modifications can be discussed with TOL on a case-by-case basis. A. Site 1. Site will be owned by the Town of Leesburg and be of adequate size for station infrastructure, roads, turning radius, and required buffer zones. 2. Paved access (6″ of 21A

This is the fourth edition of the Water System Design Manual. Many Department of Health (DOH) employees provided valuable insights and suggestions to this publication. In particular, we are proud to recognize the members of the group at the Office of Drinking Water who worked over many months to revise this edition of the design manual:

3.0 WATER PUMPING SYSTEMS DESIGN 3.1 PUMP-FED VS GRAVITY WATER SUPPLY Water pumping is required in situations where site conditions do not favour the use of gravity supply. This may occur in irrigation or water supply projects. In either case, gravity systems tend to involve high capital costs but low operating costs. On the other hand, pumping

Design Specifications & Requirements Manual Environmental and Engineering Services Department 4-4 The Corporation of the City of London Updated: May 2010 4.3.5 Pumps Multiple pumps shall be provided and sized to provide firm capacity. When two pumps are used, firm capacity shall be maintained by one pump and shall be of the same size.

as the Town of Castle Rock Water System Design Criteria Manual (hereafter called “Criteria”). All utility reports and plans, analyses, and designs, submitted as a requirement

CHAPTER 2 – APPLICATION OF DESIGN MANUAL 2.0 GENERAL 2.0.1 This Pump Station Design Manual (PSDM) is developed for use by Consultants preparing design documents (reports, plans, specifications, estimates, calculations, and manuals) for wastewater pump stations to …

Section 4 Pump Station Hydraulic Design Procedure

water-related issues or problems. Responds to after hour and emergency situations. Monitors the security of pump stations, ground storage tanks, and elevated storage tanks. Processes work orders for field maintenance crews and water quality, ensuring proper …

This book is written for a wide variety of readers: the expert and the beginner in a design office, the project leader of a design team, the city engineer or chief engineer of a water or sewerage authority (or their subordinates) who may review plans and specifications, and manufacturers’ representatives who should know how their equipment is best applied to a pumping station.

storage needs, pump configuration and selection, discharge system size, and sump dimensions. Pump house features are identified and construction and maintenance considerations are addressed. Additionally, considerations for retrofitting existing storm water pump stations are presented. 17. Key Words Pump Station, Pumps, Storm Drain,

R&O 07-20 WASTEWATER PUMP STATIONS AND FORCE MAINS June 2007 Chapter 9 – Page 1 Chapter 9 WASTEWATER PUMP STATIONS AND FORCE MAINS 9.01 General Provisions 9.01.1 Project Management 9.01.2 Pump Station in-lieu of Gravity Sanitary Sewer 9.01.3 Basic Layout and Sizing Requirements 9.01.4 Design Procedures

This chapter describes methods for determining the required capacity and pressure for water pumping stations, presents recommendations on selecting and sizing the pumps, discusses control methods for operating pumps and provides representative examples of pumping station design. Water pumping stations are usually designed to supply water to anCurrent Sections of the Hunter Water Design Manual. The following sections of Hunter Water’s “Water and Sewer Design Manual” are currently in use: Section 4 – Sewerage Pump Stations and Rising Mains – Sept 2008 – See Note 1 below. Section 5 – Water Pumping Stations – July 2008

Please note: Water Corporation Design Standards should be used in conjunction with the Water Services Association of Australia (WSAA) Codes. We recommend that you purchase a copy of the Codes from the WSAA online bookshop. Disclaimer. Please read the following disclaimer before …

17/07/2009 · Booster Pump Station Design- Public Water System Booster Pump Station Design- Public Water System cuels (Civil/Environmental) (OP) 16 Jul 09 19:32. I am designing my first Booster Pump Station. The pump station will be pumping from a storage tank to a higher pressure zone system. There will be three pumps, (1) 1900 gpm (150 hp) pump and (2) Duty pumps 45 gpm (2hp). They will be …

To pump water of a driven well, a submerged pump should be used. 9.2 Control of Delivering Capacity. Capacity of a pump station can be controlled with the simultaneous application of pumps of different delivery capacity. For one delivery pipe a maximum of three pumps, with intermittent running, with revolution control throttling, and bypass can

05/05/2010 · T-T’s range of package pumping stations provide an efficient and economical way of installing a sewage/drainage pumping station. Each of our package pumping

Pipeline Design Manuals. 2019 Pipeline Design Manual (Draft) – Draft 2019 Pipeline design manual is posted for review and comment. Revisions are marked in RED text. Submit comments, requests for correction or changes on these revisions at the link below and indicate 2019 draft PDM in the revision field. The deadline for comments on these revisions is July 31, 2019.

The proper design of the pump station is crucial in order to achieve an optimal and trouble-free environment for the pumps. Xylem’s experience is unparalleled and the company’s reach is global. We are 12,000 people unified in a common purpose – to create innovative solutions to our world’s water needs. Developing new technologies that will improve the way water is used, conserved and re

Design of Sewage Pumping Stations

Pump station design manual SlideShare

New Wastewater Pumping Station Development Manual

Booster Pump Station Design- Public Water System Water

Appendix 10-B Pump Station Hydraulic Design Example

HEC 24 Highway Stormwater Pump Station Design

Pumping Station Design ScienceDirect

https://en.wikipedia.org/wiki/Lagoon_Creek_Pumping_Station

Clean Water and Pump Station Design Romtec Utilities

Wastewater Pumping Station Standard Specification

Pump Station Design Guidelines Second Edition

Supplement to the WSAA Sewage Pumping Station Code of

For Infrastructure Master Program Engineering Faculty-IUG

This chapter describes methods for determining the required capacity and pressure for water pumping stations, presents recommendations on selecting and sizing the pumps, discusses control methods for operating pumps and provides representative examples of pumping station design. Water pumping stations are usually designed to supply water to an

CHAPTER 10 PUMP STATIONS michigan.gov

3.0 WATER PUMPING SYSTEMS DESIGN 3.1 PUMP-FED VS GRAVITY WATER SUPPLY Water pumping is required in situations where site conditions do not favour the use of gravity supply. This may occur in irrigation or water supply projects. In either case, gravity systems tend to involve high capital costs but low operating costs. On the other hand, pumping

Flygt Water and Wastewater Solutions Xylem US

The proper design of the pump station is crucial in order to achieve an optimal and trouble-free environment for the pumps. Xylem’s experience is unparalleled and the company’s reach is global. We are 12,000 people unified in a common purpose – to create innovative solutions to our world’s water needs. Developing new technologies that will improve the way water is used, conserved and re

New Wastewater Pumping Station Development Manual

For Infrastructure Master Program Engineering Faculty-IUG

storage needs, pump configuration and selection, discharge system size, and sump dimensions. Pump house features are identified and construction and maintenance considerations are addressed. Additionally, considerations for retrofitting existing storm water pump stations are presented. 17. Key Words Pump Station, Pumps, Storm Drain,

HEC 24 Highway Stormwater Pump Station Design

New Wastewater Pumping Station Development II. Pump Station Design Criteria The design criteria listed below are guidelines only, and site-specific modifications can be discussed with TOL on a case-by-case basis. A. Site 1. Site will be owned by the Town of Leesburg and be of adequate size for station infrastructure, roads, turning radius, and required buffer zones. 2. Paved access (6″ of 21A

Pumping Station Design Revised Third Edition

Water Corporation of WA Design standards

Pump station design manual SlideShare

17/07/2009 · Booster Pump Station Design- Public Water System Booster Pump Station Design- Public Water System cuels (Civil/Environmental) (OP) 16 Jul 09 19:32. I am designing my first Booster Pump Station. The pump station will be pumping from a storage tank to a higher pressure zone system. There will be three pumps, (1) 1900 gpm (150 hp) pump and (2) Duty pumps 45 gpm (2hp). They will be …

Package Pumping Station Planet Range T-T pumps YouTube

Packaged Pump Stations Xylem US

New Wastewater Pumping Station Development Manual

This is the fourth edition of the Water System Design Manual. Many Department of Health (DOH) employees provided valuable insights and suggestions to this publication. In particular, we are proud to recognize the members of the group at the Office of Drinking Water who worked over many months to revise this edition of the design manual:

Water Corporation of WA Design standards

However, a pump station becomes necessary when gravity outfalls are not economically or engineeringly feasible. The need for pump stations is a function of the highway geometric design rather than of climatic factors. Planners can design pump stations to be unobtrusive, efficient, and reliable.

Pump Station Design Guidelines Second Edition

Pump Stations 10-8 MDOT Drainage Manual 10.3 GENERAL DESIGN CRITERIA The following pump station recommendations are being made with the objective of minimizing the cost of design, construction, operation, and maintenance of highway stormwater pump stations while remaining consistent with the practical limitations of all aspects.

Wastewater Pumping Station Standard Specification

New Wastewater Pumping Station Development Manual